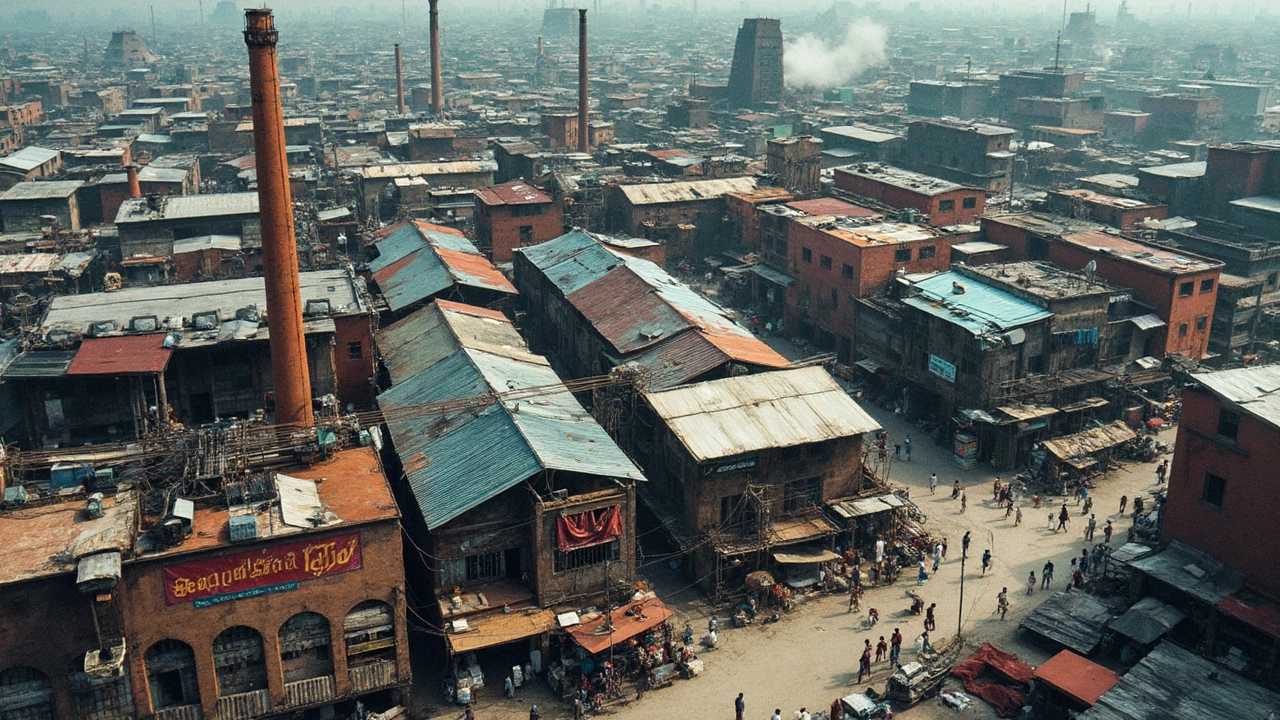

Setting up a small factory in India can feel a bit like putting together a giant, expensive puzzle. First up, you gotta think about where you want to plant your factory roots. Urban areas might seem flashy, but they come with a heftier price tag for land compared to more laid-back rural spots.

Once you've nailed down a location, construction is the name of the game. Costs can vary widely, depending on the region and the materials you choose. Pro tip: Consider using local resources whenever possible. It'll save some cash and support local businesses.

Let's not forget machinery. Depending on what you're producing, machinery can be a major chunk of your budget. There's a nifty way to ease this burden—secondhand equipment. It's a solid option if you're looking to save without compromising too much on quality.

- Initial Sizing and Planning

- Land and Construction Costs

- Machinery and Equipment Investment

- Operational Expenses and Tips

Initial Sizing and Planning

So, you’ve decided to venture into the world of small factory setups in India. That's exciting! But before the hammers start swinging, there's some groundwork to lay out. Let's dive into the nitty-gritty of sizing and planning your factory. Whether you want to put together a small manufacturing unit or delve directly into a niche market, **initial sizing** is key.

Understanding Your Needs

The first step is to understand the scale of operations you need. Are you crafting artisanal chocolate bars or are you eyeing mass production of machine parts? Smaller units like studios might differ vastly in requirements compared to traditional manufacturing plants. This will impact everything from space requirements to the kind of machinery you’ll need.

- Product Line: Clearly define what you're going to produce and how varied your product line will be.

- Production Volume: Determine the quantity you plan to produce daily or weekly.

- Flexibility: Assess how much room you need for future expansion.

Budget Constraints

Once you know what you need, it helps to tie that back to your budget. A small factory doesn't mean compromise; it means smart planning. Factor in not just the initial setup costs but also recurring expenses like electricity and maintenance. Remember, every penny counts.

Location, Location, Location!

Your factory’s location can waive or whack your budget. Urban spots mean a bigger dent in your wallet but could offer benefits like better transportation links. Meanwhile, rural areas spell savings on land but may need more investment in infrastructure. Think long term and weigh the pros and cons.

Making It Happen

Consider drafting a business plan. It not only helps you focus but might open doors for loans or investors. Speaking of loans, India has some schemes focused on micro, small, and medium enterprises (MSMEs). Take advantage!

Here's a sample layout of a budget plan for initial sizing and planning, based on a typical small manufacturing setup:

| Category | Estimated Cost (INR) |

|---|---|

| Land Acquisition | 5,00,000 - 10,00,000 |

| Construction | 15,00,000 - 25,00,000 |

| Machinery | 10,00,000 - 20,00,000 |

| Miscellaneous | 2,00,000 - 5,00,000 |

Factoring in these elements early can steer your journey toward a successful factory setup right here in India.

Land and Construction Costs

Alright, so you’ve got big plans for your small factory, but let’s talk about where this masterpiece is going to stand. The cost of land in India is a pretty big deal and varies hugely depending on the location. If you’re looking at big cities like Mumbai or Delhi, brace yourself for some serious price tags. We’re talking about approximately INR 5,000 to INR 25,000 per square meter for urban locations. But if you mosey on over to smaller cities or rural areas, you might find land going for around INR 500 to INR 5,000 per square meter. Obviously, it’s all about the trade-off between being closer to your market versus keeping your land costs low.

Construction costs, on the other hand, also have their unique flavor. On average, building a small factory can range from INR 1,000 to INR 5,000 per square foot. This covers everything from the foundation to the final touch-ups. If you’re on a tight budget, consider simplified designs or prefab structures—they can cut costs big time and speed up the process too.

Breaking Down Construction Expenses

Here’s a simple way to see where your money's headed:

- Materials: Cement, steel, bricks—all those basics come first. Prices can fluctuate, so keeping an eye on the market is key.

- Labor: Hiring skilled workers is another major chunk. This varies by region and the skill level required.

- Permits and Approvals: Don’t forget the paperwork. Permits and other legalities can take both time and money, so factor that in your planning.

Cost-saving Tips

Want to make the most out of your budget? Tap into local materials and suppliers to cut down on transport costs. Also, collaborating with local contractors could land you some favorable deals, not to mention the added benefit of supporting local businesses.

Machinery and Equipment Investment

Alright, diving into the world of machinery and equipment investment can be a bit like stepping into an entirely new ecosystem. Your machine purchases can make or break your factory's efficiency and output. The budget here can be tight or flexible, depending on what you're planning to manufacture.

New vs. Secondhand Equipment

When it comes to deciding what kind of equipment to buy, you've got two options: shiny and new or tried and tested. New machinery often brings more reliability and fewer repairs in the early years but can cost a small fortune. On the other side, secondhand equipment might not have the latest features, but it can be a budget-friendly lifesaver if you're looking to start things off without breaking the bank.

It's a good idea to calculate the cost-benefit ratio. Are the savings from buying used gear enough to cover potential downtimes or upgrades soon after? A little math here can save a big headache later.

Must-Have Equipment Features

Some features might be non-negotiable depending on what you're producing. Automatic controls, ease of maintenance, and safety features are just a few aspects you can't ignore. Keep in mind that sometimes spending a little extra on these features can ramp up output efficiency, saving cash in the long run.

Pro Tip: Always ask for a warranty or guarantee period, even for secondhand equipment. It acts like an insurance policy, giving peace of mind.

Estimated Costs and Budget Allocation

The numbers can be eye-watering if you're starting out with the latest full-scale, automated machines. A ballpark figure for setting up a modest assembly line could range from INR 10 lakh to INR 50 lakh, depending on your industry. This includes installation and minor customizations needed to get things rolling.

| Type of Equipment | Cost Range (INR) |

|---|---|

| Basic Assembly Machines | 5 lakh - 15 lakh |

| Advanced Automated Lines | 20 lakh - 50 lakh |

| Packaging Units | 1 lakh - 5 lakh |

Remember, your spend on machinery and equipment determines a lot about your operational efficiency, so make sure you research thoroughly and allocate your budget smartly. Happy investing!

Operational Expenses and Tips

Alright, let's dive into the world of operational expenses that come with running a factory in India. Keeping these costs in check is crucial for your small manufacturing unit to thrive. Operational expenses often include things like electricity, water supply, labor wages, and maintenance—all the behind-the-scenes stuff that keeps your factory humming.

Electricity and Water

Utilities are a big one. Factories guzzle electricity, so look into energy-efficient machinery. It could make a huge dent in your bills. Water is critical too. Efficient usage can save money, so fix leaks and consider a recycling system if it fits your budget.

Labor Wages

When it comes to labor wages, the rates depend on the location and the skill level required for your operations. Larger cities mean higher wages. However, it's worth noting that offering competitive wages can lead to lower turnover and better productivity.

Maintenance and Repairs

Don't underestimate the importance of a solid maintenance strategy. Regular check-ups on your machinery can prevent costly breakdowns. Keeping a maintenance schedule will minimize unexpected expenses and keep everything running smoothly.

Pro Tips

A little foresight goes a long way. Here are some tips to keep your operational expenses in check:

- Track your expenses meticulously—apps can help you stay organized and spot overspending early.

- Invest in your team. Training programs might look like an upfront cost, but they pay off in efficiency and morale.

- Explore government incentives for small manufacturers. There may be subsidies or tax benefits available.

Let's also consider a cost breakdown that might be typical for a small factory:

| Expense Category | Approximate Monthly Cost (INR) |

|---|---|

| Electricity | 50,000 - 80,000 |

| Water | 10,000 - 20,000 |

| Labor | 200,000 - 400,000 |

| Maintenance | 20,000 - 30,000 |

All this can feel overwhelming, but with a strategic approach, your small factory in India can be a buzzing hub of productivity without bleeding money.